A custom transformer can significantly boost system performance when it’s designed specifically for your application instead of using a generic off-the-shelf unit. Here’s how it helps, broken down by performance dimensions.

1. Higher Electrical Efficiency

A custom transformer can be optimized for:

- Exact input voltage range (e.g., 110 V only, 230 V only, or narrow tolerance)

- Exact load profile (continuous vs pulsed current)

- Operating frequency (50/60 Hz or high-frequency SMPS)

Benefits

- Lower core and copper losses

- Reduced heat generation

- Smaller heatsinks or no active cooling

- Better overall system efficiency (often +3–10%)

2. Improved Voltage Regulation & Stability

Generic AC-DC supplies are designed for “average” use cases.

A custom design can deliver:

- Tighter voltage regulation (±1% or better)

- Lower output ripple and noise

- Better transient response to load changes

Why this boosts performance

- Sensitive electronics (MCUs, FPGAs, RF, audio, sensors) operate more reliably

- Less need for downstream regulators

- Reduced timing errors, data corruption, or analog distortion

3. Lower EMI & Noise

Custom transformers can be designed with:

- Optimized winding geometry

- Electrostatic shields

- Custom core materials

- Proper grounding and isolation strategy

Result

- Lower conducted and radiated EMI

- Easier compliance with FCC / CE / CISPR standards

- Improved signal integrity in high-speed or analog circuits

4. Better Thermal Performance

By tailoring:

- Core size and material

- Wire gauge

- Duty cycle assumptions

You get:

- Cooler operation at nominal load

- Longer component lifespan (every 10 °C drop roughly doubles lifetime)

- More stable performance in hot environments

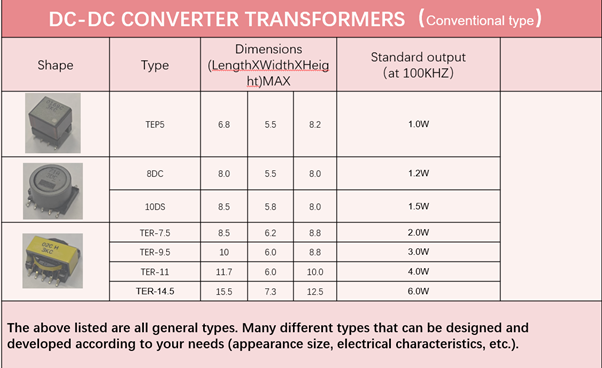

More information can be found on the datasheets:

If you want more information or if you have any questions, please contact Nijkerk Electronics!