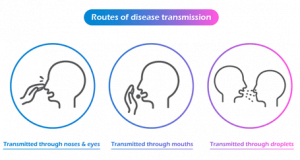

COVID-19 virus broke out globally in 2019. A large-scale epidemic caused casualties, affecting daily life and economic activities. The risk of infection will be increased through close droplets, direct or indirect contact with people or objects carrying viral oral and nasal secretions, or staying in a confined space within 2 meters of the confirmed patient for a long time without respiratory protection.

In the surrounding environment of life, which is very easy for you to contact the related public facilities like: ticket purchasing machine, food ordering machine, medical system, ATMs. etc. If inadvertently touching these facilities, you will be exposed to the risk of infection. Disinfection cannot be performed immediately, it can easily lead to a large scale pandemic. Nowadays, in such an advanced-technology environment, 3C products are everywhere. Everyday use in 3C products will leave sweat or skin grease on them which will breed bacteria or infections causing diseases.

Therefore, Winstar Group comes up with a solution, which is to destroy bacteria or germs tissues before spreading, or the general environment that is difficult for bacteria to survive. Weaken its infectious power, and effectively control the possibility of infection. Winstar actively develops a variety of product options with antibacterial effects, which can inhibit the growth of bacteria and germs on the surface of related products. Please feel safe when using related antibacterial series products, because Winstar will protect your health and safety.

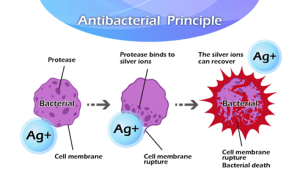

Antibacterial principle:

When bacteria or germs touch the surface of the product, the silver ions on the product surface will contact the cell membrane of the bacteria or germs. The silver ions will undergo a biochemical reaction with the protease of the cell membrane, resulting in biological inactivation (bioinactivation). During the reaction of the two, silver ions will quickly and effectively destroy bacteria and germs; afterward, silver ions will be released from dead bacteria and germs, and then continue to carry out repeated biochemical reactions to other contacting live bacteria and germs until the bacteria and the germs are eliminated. As shown in Figure 2. The effect of silver ions is a long-term bactericide with a long-lasting effect.

Winstar launches related antibacterial series products, which will retain antibacterial effect after long-term use. The biological test results show that it is effective in inhibiting Escherichia coli and Staphylococcus aureus, and the antibacterial effect reaches more than 99%, and the antibacterial ability won’t decrease as time goes by.

Figure 2: Principle of antibacterial

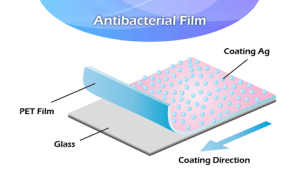

Antibacterial Film:

The silver ion material is evenly spread on the PET substrate in a coating process. The silver ion coating layer is tightly combined with the PET after thermal curing treatment to form an antibacterial protective film. as shown in Figure 3.

Figure 3: Antibacterial Film

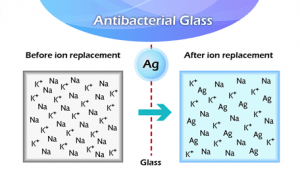

Antibacterial Glass:

It is formed by using high-temperature ion exchange method to exchange and combine silver ions with other ions in glass. As shown in Figure 4, the antibacterial effect of the antibacterial glass is very good. At the same time, its optical characteristics and surface scratch resistance both have excellent performance. For product portfolio, design considerations can be integrated with cover glass.

Figure 4: Ion exchange principle of antibacterial Glass

Antibacterial product solution: (as shown in Figure 5)

- Plan and design with antibacterial display and related products according to customer requirements.

- Plan and design of LCM/CTP/RTP products with antibacterial film.

- Plan and design of LCM/CTP/CG products with antibacterial glass.

- Provide suggestions considering product environment and applications.

Figure 5: Antibacterial display product plan

Antibacterial product applications

Regarding antibacterial issues, whether it is for general household use, industrial control, medical care, mass transportation systems, personal 3C products, etc. (as shown in Figure 6), Winstar can provide suitable product solutions and professional services, which are superior to other peers in the industry. Including users and applications circumstances, operating functions, special environments and other needs are considered, providing material selection, human factor design, high-quality photoelectric characteristics, best product combination, software firmware design, optimized operating interface, etc, to meet specification requirements, and innovate antibacterial optimization product solutions.

If you want more information or if you have any questions, please contact Nijkerk Electronics.