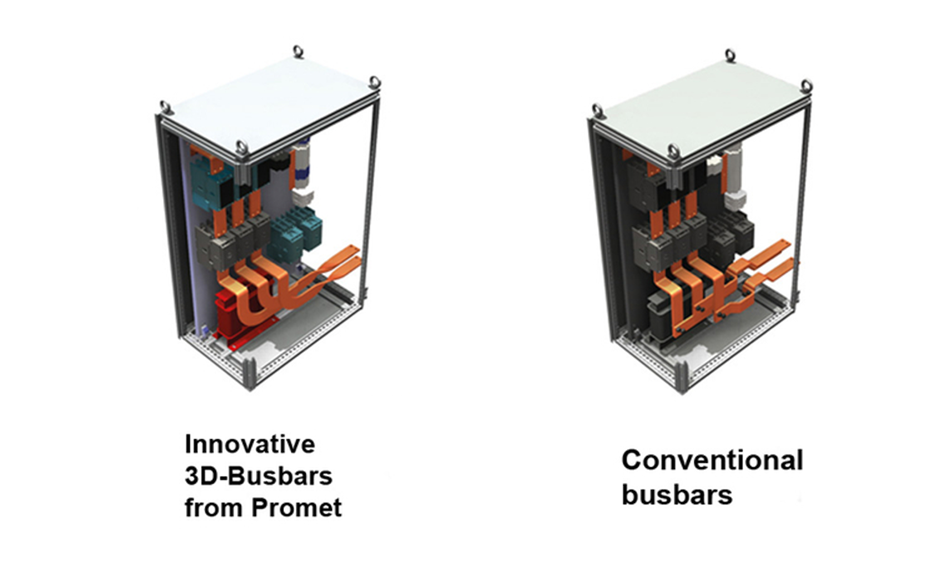

The conventional connection of a point-to-point busbar connection in the past was based on a screw connection, partially of several busbars. Seen from a pure cost-benefit analysis, this was a costly solution. From the risk analysis, there was a serious risk of loose connections caused by shock and vibration loads and torque problems when tightening the screws etc.

The Promet 3D technology reduces costs enormously. A homogeneous point-to-point connection ensures the best possible connection and reduces the risks considerably. In purchasing as well as in logistics.

Benefit for Customers and Users

• Homogeneous uninterruptible point-to-point connection

• No overlap at points of contact -> reduction of raw material

• Risk minimization

• Increased service life

• Up to 20% reduction in assembly time

• No mounting material for the connection of busbars

• Reduced items -> Easier purchasing and less stock keeping

• Parallel guided wires are available

Busbar Comparison

Example: 60 x 10 mm Copper = 26% reduction of weight

For more information about Promet Busbars, please contact Nijkerk Electronics.